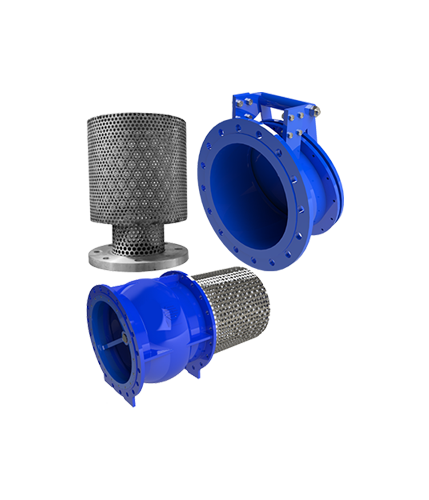

Swing Check Valve

When the water in the pipeline starts and moves in the direction of flow, the flapper is opened and full passage is provided and the valve starts to operate. The flapper is designed to provide full passage. If the flow stops, it closes and does not allow flow in the opposite direction. Sealing is ensured by fitting the flapper to the metal site surface. Sealing can be provided by covering the flap with rubber. It can also be counter-weighted to provide flow control. Can be used in vertical pipelines. Maintenance and repair is quite easy. When the top cover bolts are removed, the valve and connection mechanism can be taken out. Provides complete sealing at low pressures. During installation, the valve must be fitted to the line according to the arrow marking on the valve.