Quality is our priority. Therefore, with the help of our qualified team, we guarantee the best quality to our customers. We promise you complete satisfaction.

The commercial success of our company stems not only from our ability to meet our customers’ needs and expectations accurately, timely, and cost-effectively but also from our high flexibility.

Our Quality Policy

ESVANA implements its management approach in accordance with the ISO 9001 Quality Management System.

ESVANA gives importance to occupational health and safety of factory visitors and employees at every stage of production and management. It continues proactive work to eliminate potential risks related to occupational health and safety and constantly improves to prevent work accidents and occupational diseases. The company operates within the scope of the ISO 45001 certificate.

ESVANA, which has the ISO 14001 Environmental Management System, prioritizes environmental policies and continues its recycling efforts within the zero waste project.

ESVANA Production

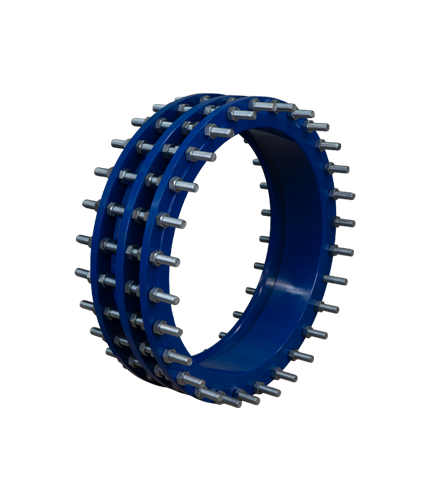

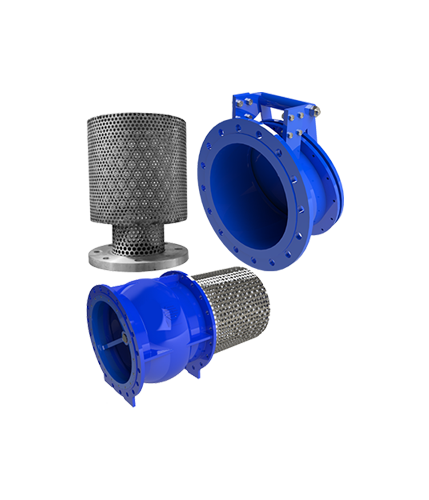

The manufacturing of our products is carried out entirely in-house at ESVANA, starting from design and modeling, mold making, ductile casting, machining, to pre-coating and coating operations.

Quality is emphasized at every stage of production, and compliance of each produced part with production processes is controlled. Our factory is equipped to produce and test valves ranging from DN40 to DN2400 in diameter and pressure classes up to PN10-PN40.

Production Capacity

Our factory, covering a total area of 16,000 m² with 12,000 m² closed and 4,000 m² open spaces, produces with more than 100 experienced personnel meeting customer needs. We produce approximately 10,000 valves annually with an average raw material consumption of 3,000 tons per year.

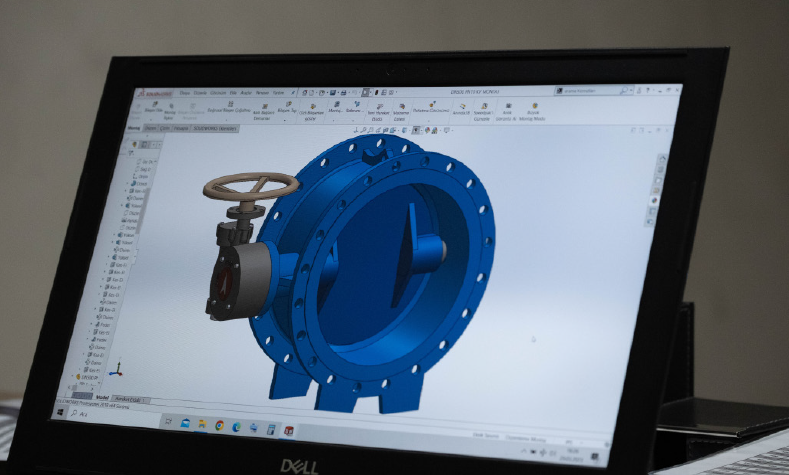

R&D Analysis and Simulation

Our factory conducts quality controls using state-of-the-art devices in its own laboratory. The R&D unit performs design analyses with CFD software, emphasizing continuous innovation and development in production. Dimensional controls of produced parts are carried out at the CMM center to ensure ongoing production quality.

All parts are subject to quality control before assembly and traceability is ensured through the ERP system. Finished products undergo hydraulic tests to prepare for product acceptance.

Flow Tests

Valve flow characteristics (Kv) measurements and cavitation monitoring tests are conducted in our factory according to the TS EN 1267 standard for diameters up to DN 40-DN 350. Flow characteristic tests are practically applied on butterfly valves, check valves, gate valves, needle valves, and pressure control valves, with CFD analyses used for compatibility comparison. Our R&D unit improves designs based on these results.

Painting and Control System

Our products are coated with thermoplastic epoxy powder paint (WRAS approved) in accordance with standards and the coating manufacturer's material data sheet.

Post-Painting Tests

Pull-Off Adhesion Test, Spark (Holiday) Test, Coating Thickness Measurement