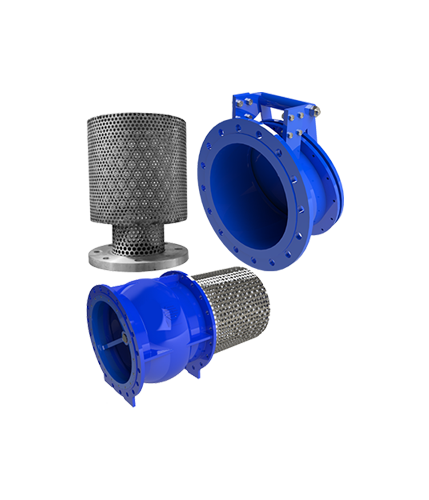

Dynaic Triple Function Air Release Valve

Air valves are critical water control elements in pressurised closed network systems. According to the flow conditions, they operate spontaneously. They ensure that the flow continues without damaging the line by acting during the commissioning and operation of the water lines and during the discharge of the line. Air valves should be placed in accordance with the project. Air valves provide controlled discharge of the air in the pipe while water is filled into the network. It ensures the continuity of the flow by discharging the air accumulated at critical points as long as the operation is used. When there is any disruption in the system that disrupts the flow, it is opened and prevents the formation of vacuum by providing sufficient air intake into the pipe. In this way, no collapse occurs in the pipes. Longitudinal cracks are formed in the collapsed pipes and become unusable. When the flow is interrupted, the rupture of the flow creates a water ram blow and causes the pipe to burst at high pressures, the water ram blow is prevented by the air valve by the air into the pipe. In pressurised pipe systems, system protection is provided by non-impact dynamic air valves. ESVANA Pulseless Air Valves have three float valves and four functions. Quickly discharges air from the outlet nozzle during filling water into the pipes. This ensures fast filling of the pipe with water. When the air discharge speed from the valve reaches 30 m/s, the upper float closes and starts to discharge the air through the orifice on it, so that the air in the pipe cushions the water and prevents the water from hitting the equipment and creating an impact. When the pipe is completely filled with water, the floats rise up with the buoyancy of the water and close the air and water outlet, the air bubbles moving with the water in the pipe accumulate inside the air valve and this accumulated air is discharged through the metal orifice in the middle float. In this way, the air accumulated in the pipes does not disturb the flow. If the flow is disturbed for any reason, it causes reverse flow in the pipes or the water in the pipes is discharged too fast. This creates a vacuum in the pipes and causes pipe collapse. The air valve opens in case the pressure inside the pipe is smaller than the external pressure, allowing air to enter the system and the pressure is balanced and no collapse and crushing of the pipes occurs. Air valve floats are made of HDPE material, high resistance to impact and abrasion. The small orifice drain orifice is stainless steel. (AISI 420) Gaskets are EPDM material. Floater guides and seat ring are made of stainless steel. (AISI 420) Air valve inlet diameter and discharge diameter are equal to each other. The air valve protection filter is made of stainless steel sheet and the total area of the filter holes is larger than the valve outlet area. Acceptance tests are in accordance with TS EN 1074-4 standard.