Excellence in Sealing: The Technical Advantages of Esvana Produc

The safe and efficient operation of fluid systems depends not only on the quality of the equipment used but also on sealing performance. As Esvana, we offer our engineering expertise in the valve sector to our customers through products that feature high sealing capacity, long service life, and compliance with standards.

In every product, there is not just a physical part but a reflection of attention to detail and a continuous improvement mindset. Sealing is one of the most delicate and critical outcomes of this approach.

From Design to Production: Engineering Focused on Sealing

Sealing performance is directly related not only to the quality of the gasket but also to the valve body design, surface treatment quality, material selection, and manufacturing precision.

At Esvana, in every new product development process, we address all these parameters in accordance with international standards and test our products according to TSE and ISO norms.

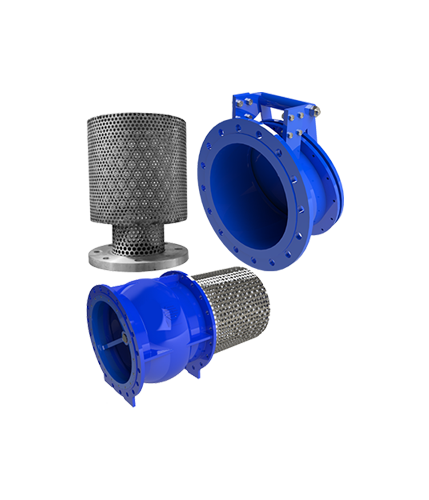

Especially in our butterfly valves, strainers, check valves, and pressure control products;

• Double eccentric designs,

• CNC machining precision that ensures surface smoothness,

enable us to provide superior sealing against system pressure.

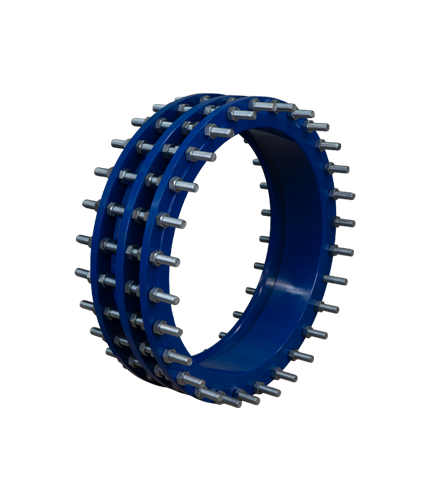

Project Suitability and Wide Product Range

Our product portfolio caters to many different applications such as infrastructure systems, industrial processes, fire safety, and water management, offering valve options suitable for every project.

Accordingly;

• Different pressure classes (PN10, PN40),

• Wide diameter ranges (DN40–DN2400),

• Manual, pneumatic, or electric actuator compatible options

are designed to maintain sealing criteria.

Additionally, we offer project-specific sealing solutions according to requested applications and provide product customization possibilities based on special gasket types, material compositions, or coating preferences.

Certified Quality Assurance

We secure sealing performance not only through production but also via certification and testing processes.

Esvana products are manufactured in compliance with the ISO 9001 quality management system and;

• Hold international certifications such as WRAS,

• Comply with product test standards like EN 1267.

Every product undergoes pressure and sealing tests before shipment and is delivered to the customer with inspected, certified, and reliable test documentation.

Performance Not Only Today, But Also Long-Term

At Esvana, our goal in sealing is not only high performance at the start but also engineering quality that preserves form and function over time. Accordingly:

• Corrosion-resistant internal/external surface coatings,

• High temperature and pressure tolerances,

• Easy-to-service part replacement structures

extend the product lifespan and minimize maintenance costs.

We Know Trust Starts in the Details

Sealing is one of the most critical criteria determining whether a system will operate properly. At Esvana, we act with the responsibility of this awareness and continue to produce reliable and long-lasting products at high engineering standards.